Apeco possess extensive experience in the conveyance of various materials. We offer a variety of services ranging from equipment planning to after-sales maintenance and technical support. The services offered by Apeco are flexible, as they are tailored to the needs and wishes of each client. Our production process is founded on a carefully thought-out step-by-step approach, where each step is a prerequisite for the next. This enables us to provide services at all stages, from concept design to the supply of fully functional value-adding equipment.

Planning

Drafting of preliminary designs

Technical consultation

Cost–benefit calculations

After-sales maintenance and technical support

Warranty

Maintenance agreements

Calibration of belt weighers

Planning

- Drafting of preliminary designs

- Technical consultation

- Cost–benefit calculations

Planning is of critical importance in the production process: proper planning ensures that the finished solution is suitable for the production environment and fulfils its purpose while meeting the client’s expectations to the maximum extent possible. As experienced professionals, we are able to offer our clients expert consultancy, measurement, design drafting, and project budgeting services.

By analysing every available option and working together with the client, our team will help each client find the most suitable solution for them.

Design

- Creation of 3D models

- Preparation of drawings

- Preparation of instructions for use

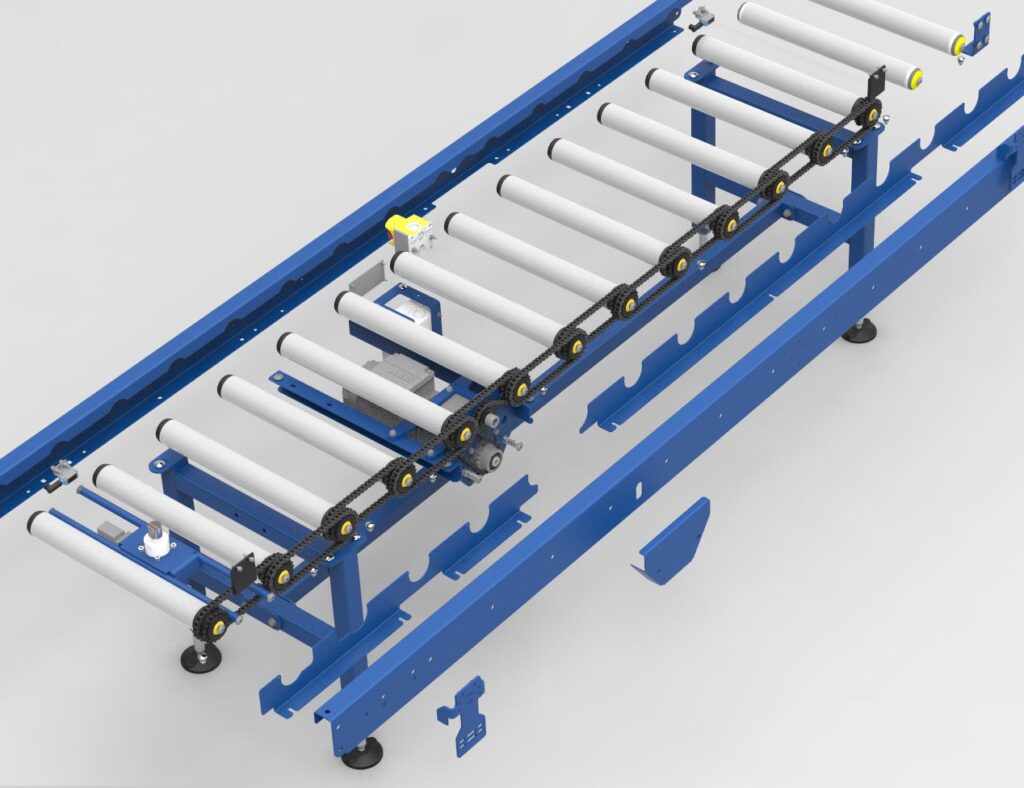

Precise and skilful design is the cornerstone of efficient production. Design work is aimed at developing products that are fully tailored to their environment. Proper design is key to avoiding potential errors in the production of machinery. Using licenced Solid Edge CAD software, our team of professional and creative engineers is able to employ the best practices for designing machinery.

The thousands of hours of experience in designing material handling systems and related products under our belt have equipped us to design flawless solutions that are both durable and easy to maintain.

Production

- Welding and mounting (TIG, MIG/MAG, MMA)

- Assembly (up to 8t)

- Testing

- Packaging

With finished drawings and specifications, we can get started on the production of the planned equipment. We are prepared to handle the entire production process for you, including the preparation of workpieces, welding, painting, assembly, testing, and packaging. To ensure high production quality, we have access to a team of trained and experienced welders and assembly workers.

At the end of the production process, you will have a finished product that meets all of the project specifications. All products will be carefully packaged to prevent damage during transport.

Installation

- Lifting operations

- Mounting

- Weldment assembly

We install equipment produced by Apeco as well as other manufacturers. For equipment manufactured by Apeco, we also carry out start-up tests and product delivery. Depending on the scale of the project, installation operations are managed either by an experienced project manager or site manager. If necessary, our team of skilled welders is also equipped to perform on-site assembly of steel structures.

After-sales maintenance and technical support

- Warranty

- Maintenance agreements

- Belt weigher calibration

We offer periodic maintenance, scheduled maintenance, and technical consultation for equipment manufactured by Apeco as well as other manufacturers. To prevent equipment malfunctions, our maintenance team performs thorough maintenance and checks to ensure that all components are functioning properly. If supplied with the necessary preliminary information, we have all of the required equipment at our disposal for carrying out maintenance work with high quality.

Any wear parts or components that appear in need of replacement or repair will be reported to the client, after which the client can decide how to proceed.