The Art of Cleanliness – Is Hygiene in Manufacturing a Primary or Secondary Concern?

Hygiene is something we learn from an early age, both at home and in everyday life. We understand that cleanliness has a direct impact on health and quality of life. The same principle applies in manufacturing, where equipment hygiene directly affects production reliability, downtime, employee health, and ultimately product quality and company reputation.

Yet in practice, equipment hygiene often remains in the background. Companies invest in state-of-the-art machinery and automation, while hygiene is treated as something that can be “fixed later.” In most cases, the issue is not a lack of willingness or discipline – people do their jobs as well as the environment allows. The real question is whether equipment and production lines are designed in a way that makes them genuinely easy to keep clean.

Although equipment hygiene is critical across many industries – from pharmaceuticals and water treatment to agriculture – this article focuses primarily on the food industry, where hygiene must always play a leading role. In reality, when purchasing equipment or planning production lines, discussions typically begin with productivity, speed, and return on investment. Hygiene tends to come into focus only once problems arise: cleaning takes too long, lines experience excessive downtime, or audits reveal areas that cannot be cleaned in accordance with requirements.

This is precisely why hygiene should be addressed earlier and more deliberately – not only when it becomes an obstacle.

The Importance of Hygiene in Manufacturing

Hygiene is not a separate process running alongside production. It is an integral part of how production functions.

When a production line is difficult to clean:

- dirt and moisture accumulate in hard-to-reach areas;

- the risk of bacterial growth and contamination increases;

- cleaning becomes time-consuming and costly;

- and ultimately, product quality and company credibility suffer.

It is important to understand that hygiene begins long before a machine is switched on. This is why the following questions must be considered early on:

- How is the production area designed?

- How do airflows and people move within the facility?

- Which production zones are connected?

- What type of product is handled on a specific line (e.g., raw or ready-to-eat (RTE) food)?

If these questions are not addressed from the start, improved cleaning procedures later will not resolve the underlying issues.

Ensuring Equipment Cleanliness and the Hidden Costs Involved

In practice, maintaining equipment hygiene usually means:

- additional labor time;

- more personnel;

- higher consumption of cleaning agents;

- increased downtime.

The more complex the line design, the higher these costs become.

Typical examples include:

- horizontal surfaces on frames where liquids and residues accumulate;

- pipes and cables positioned in a way that prevents proper access;

- closed profiles where condensation builds up;

- exposed threads and sharp corners that are difficult to clean;

- and many others.

These are not cleaning failures, they are design failures. Every design flaw results in manual work, increased risk, and additional costs in both time and money.

Why Equipment Design Is Critical for Hygiene?

Hygienic design means that equipment is created to be easy to clean and safe for people to work with. In practice, this includes:

- Frames and structures are designed with slopes to prevent liquid and residue buildup.

- Avoidance of large horizontal surface areas.

- Cables positioned visibly and accessibly.

- Use of open profiles or fully sealed hygienic constructions.

- Materials that withstand frequent and intensive cleaning.

Internationally, guidelines such as those issued by EHEDG emphasize hygienic design across the entire production line, not just individual machines. If even one component, such as a conveyor, is unhygienic, difficult to clean, or incorrectly selected, the entire process becomes a hygiene risk. Every detail matters.

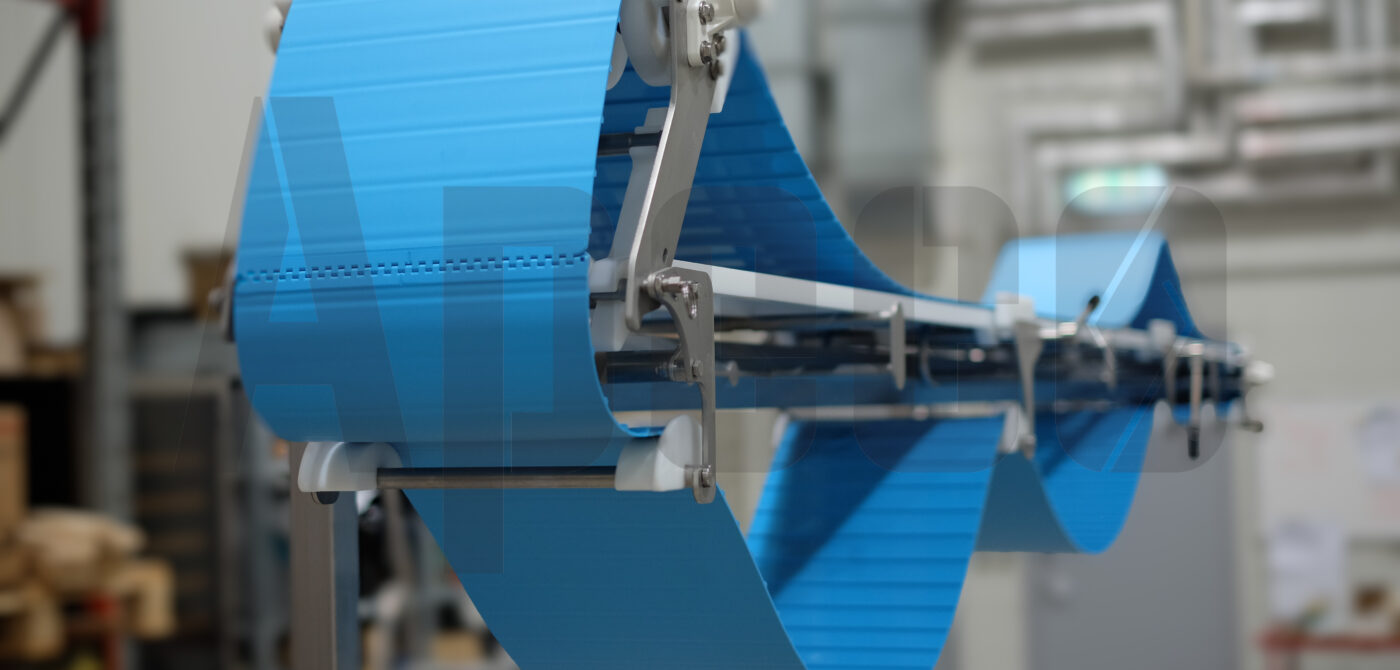

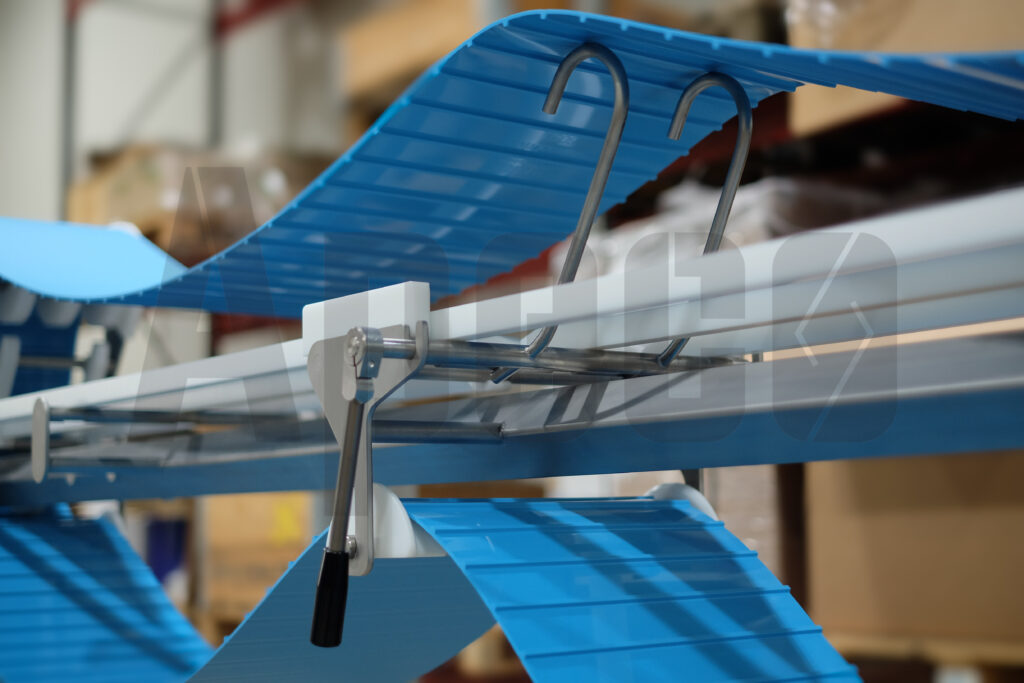

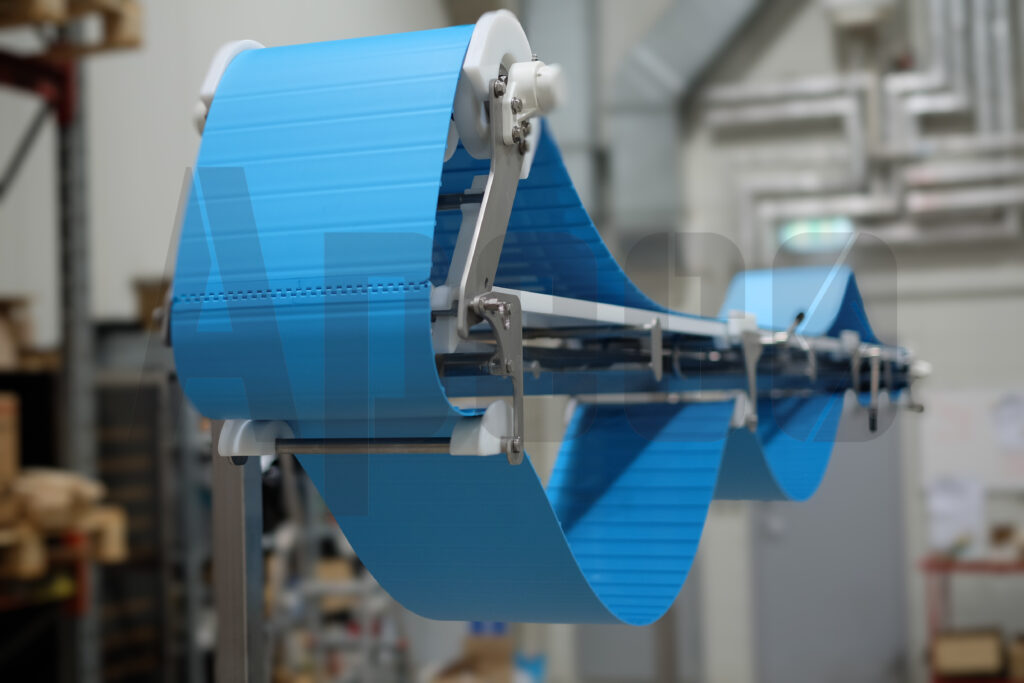

Advantages of ThermoDrive Belt Conveyors

When discussing the “peak” of hygienic solutions, ThermoDrive belt conveyor technology stands out as a clear example.

ThermoDrive is designed for environments where:

- cleaning is daily and intensive;

- downtime is critical;

- hygiene is not a “nice to have” but a strict requirement.

Its smooth surface, sealed construction, and ease of cleaning result in:

- shorter cleaning times;

- reduced water and chemical consumption;

- faster start-up of production lines;

- controlled and minimized hygiene risks.

More information about ThermoDrive can be found on our partner Intralox’s website.

Apeco Starts from the Beginning

Apeco does not start with a product – it starts with the process. Understanding the customer’s production as a whole is essential to us:

- we consider production zones;

- we assess the type of product being conveyed;

- we account for cleaning and maintenance requirements;

- we apply applicable standards and best practices;

- we take customer-specific constraints into account.

This approach leads to solutions that are not only technically sound, but genuinely support hygiene, safety, and long-term operational reliability.

In Conclusion

Equipment hygiene in manufacturing is not a narrow technical topic or merely a matter of regulatory compliance. It is a fundamental part of production performance, reliability, and everyday reality.

When hygiene is addressed only at the cleaning stage, the bigger picture is lost. In reality, hygiene begins with:

- people’s attitudes and values;

- equipment design and structural logic;

- the creation of the right preconditions.

Hygiene must be addressed consciously, understood holistically, and developed consistently. It should be discussed more broadly—not only among specialists, but also during production planning, investment decisions, and equipment procurement. The earlier hygiene is considered, the fewer compromises, delays, and risks arise later.

If you would like to discuss how to make your production easier to clean, more reliable, and future-proof, feel free to contact us.