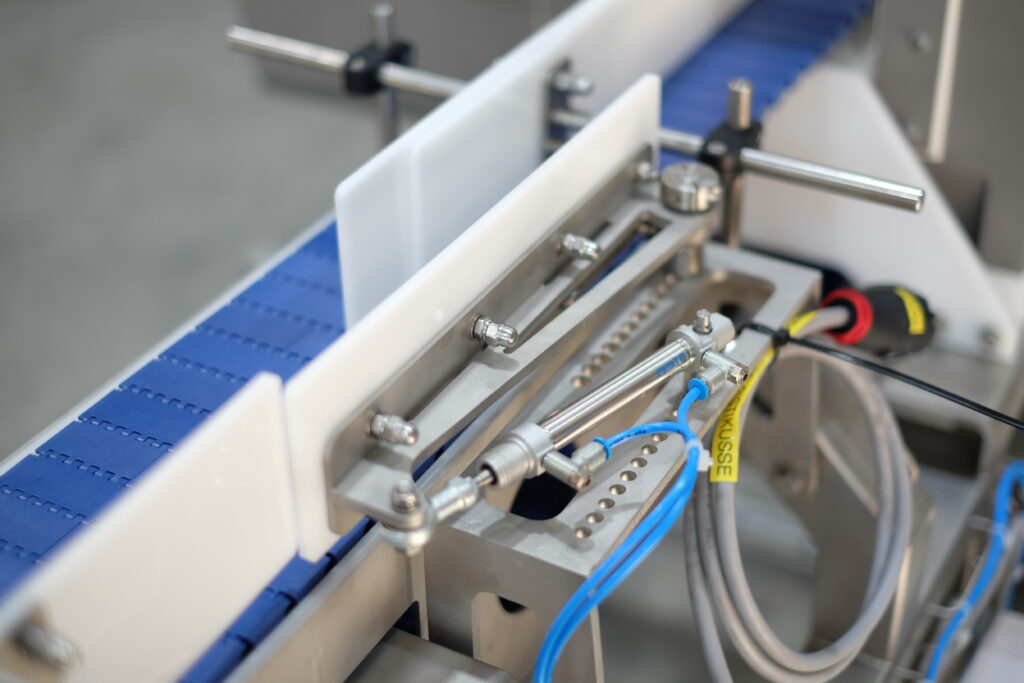

Metal-detecting belt conveyor

Metal-detecting belt conveyors are designed for the removal of off-specification products that contain metal particles from the line. The conveyor can be supplied with either a smooth PU or plastic modular belt. The most widely used off-spec product-removal technology in metal-detecting belt conveyors manufactured by Apeco is a retracting-belt reject mechanism.

For the removal of metal-containing off-spec products

For the removal of metal-containing off-spec products Advantages of Apeco metal-detecting belt conveyors

- Quick and ergonomic cleaning

- Designed in line with requirements for metal detectors

- Safe design

- FDA-compliant hygienic design

Well suited for the following industries:

- Food industry

Length: up to 6,000 mm

Width: up to 2,500 mm

Belt speed: per the technical design

Sliding surface: perforated

Conveyor drum: hot-vulcanised or chain sprockets

Conveyor belt: PU or plastic modular belt

Leg adjustability: +/-50 mm

Base frame: stainless steel

Base frame surface finish: glass-bead blasted

- Belt cleaner

- Pneumatic belt centring

- Guides on the sides of the conveyor

- Drum motor

- Acid-resistant stainless steel

- Residue collection vessel

- Control panel

- Pneumatics panel